Features

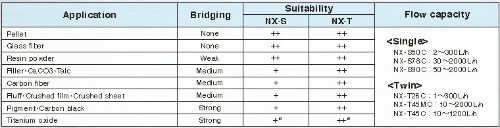

1. Bridge and segregation of materials is prevented.

2. Mass-flow and uniform rate feeding are realized.

3. Energy saving by low power.

CIRCLE FEEDER® solves every problem with powder and granular materials once and for all.

Construction and Principles of the Discharge System

1. CIRCLE FEEDER® is to be attached to the bottom of a hopper or silo.

2. On the bottom panel of the CIRCLE FEEDER®, thin, flat vanes rotate.

3. The vanes spread out and move the powder materials to the periphery of the cylinder.

4. At the periphery, the powder materials are introduced to the exhaust port by peripheral vanes and discharged.

Adjustment of Discharge rate

* Clearance adjustment of flow adjusing ring (Standard)

The feed rete is controlled with raising and lowering the height of flow adjusting bolts on the casing by turning the flow adjusting bolts.

* Rotation Speed Adjustment of Rotary Vanes (Optional)

Increases the discharging rate and lower rpm decreases it.

Mechanical type, Electrical type

◆ Manufacturer : YOSHIKAWA Corporation

◆ Exclusive Sales Agent : SAMBO Corporation